私たちの技術は、ヘミングをはじめとした曲げ加工の分野で、高い評価をいただいています。

作業効率や生産性のアップをサポートするとともに、確かな製品品質をお約束します。

また金型や搬送機といった幅広い生産設備の製作にも対応。

お客様の設備の充実化は、私たちにお任せください。

SCROLL

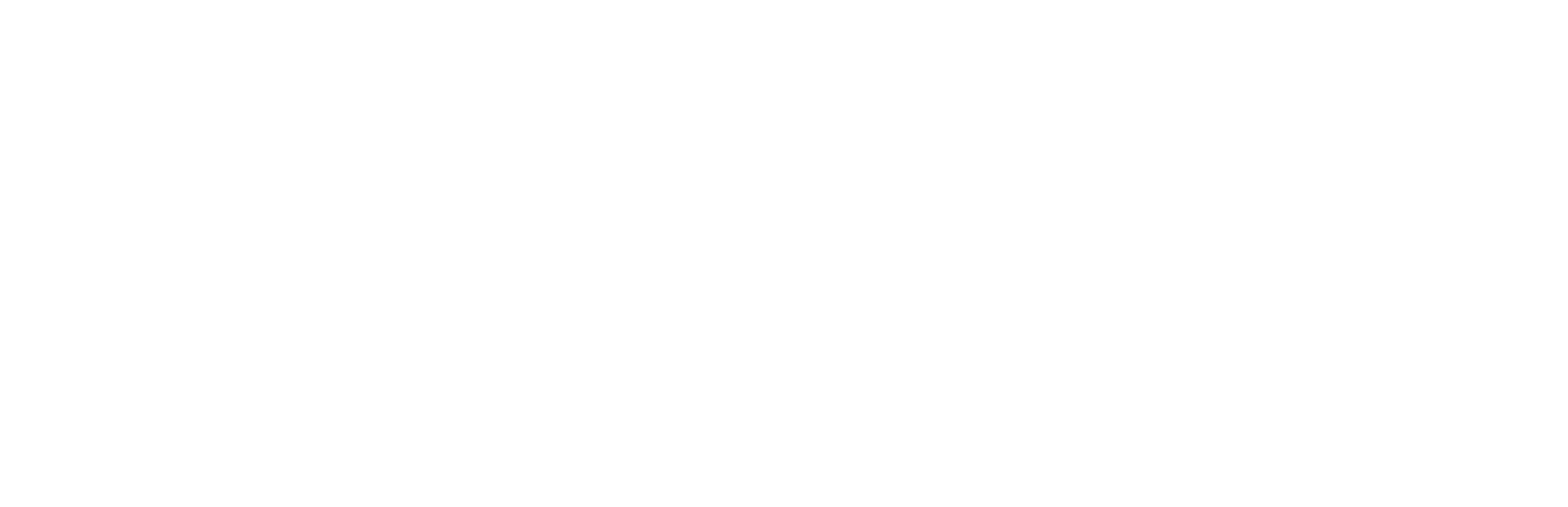

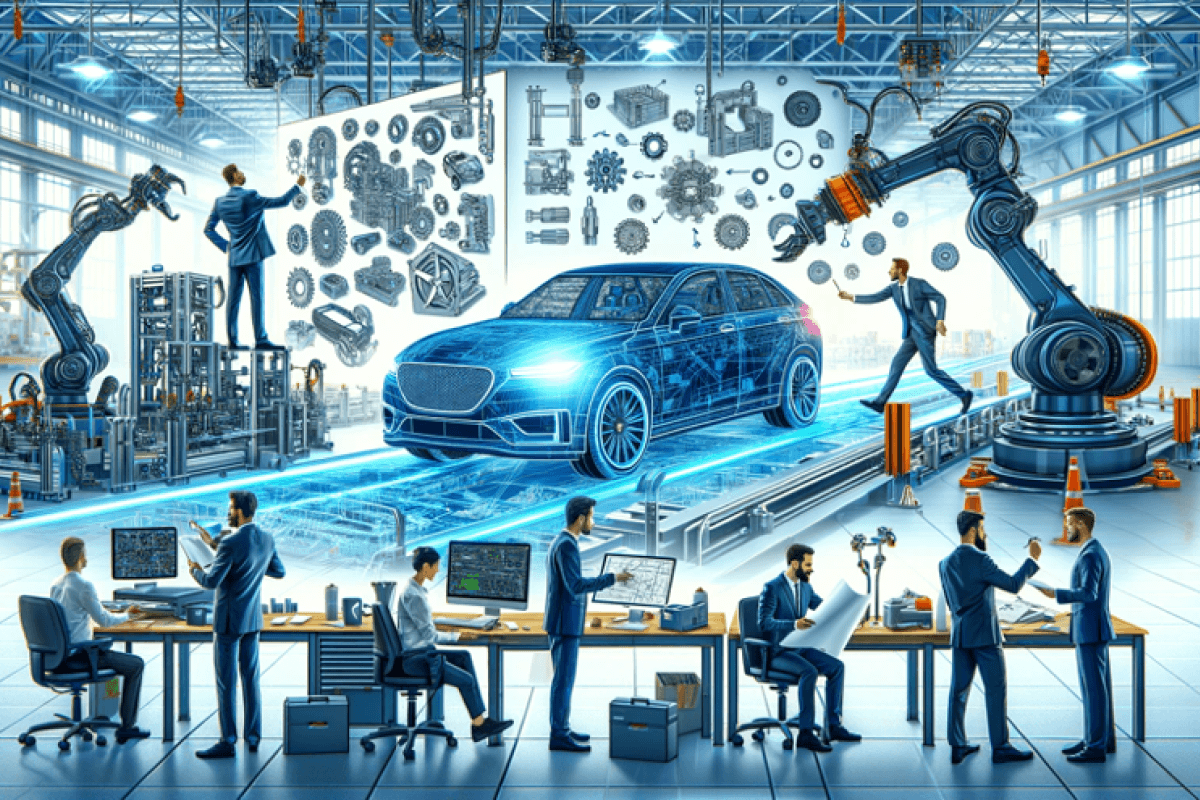

私たちは、自動生産設備を得意とする

システムインテグレーションを行う企業です。

特にヘミング加工(曲げ加工)の分野では

日本のみならず、世界でも選ばれています。

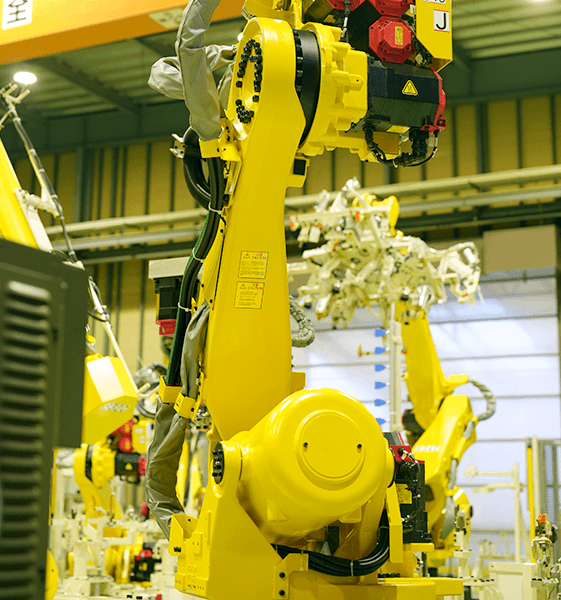

産業用ロボットやシミュレーションソフトを用いた

先進技術にも力を入れており、

高品質なものづくりで評価を受けています。

私たちの技術は、ヘミングをはじめとした曲げ加工の分野で、高い評価をいただいています。

作業効率や生産性のアップをサポートするとともに、確かな製品品質をお約束します。

また金型や搬送機といった幅広い生産設備の製作にも対応。

お客様の設備の充実化は、私たちにお任せください。

FEATURE 01

当社は「ヘミング加工」の分野で高い品質を誇ります。

ヘミング加工は、金属の縁を折り曲げて接合する技術で、私たちの高品質な加工はものづくりの精度と美しさを向上させるための核となります。創業当初からの私たちの強みであり、業界内でも高く評価されています。

FEATURE 02

生産ラインの全工程(仕様の設計から製造、トライ、最終的な据付工事、品質玉成)を一手に製作できる、私たちの「フルターンキー」サービスにより、効率的にプロジェクトを進めることが可能です。

お客様のものづくりの効率と品質を高めるための最適な解決策です。

FEATURE 03

私たちは特定の企業グループに依存することなく、多様な業界とビジネスを展開しています。

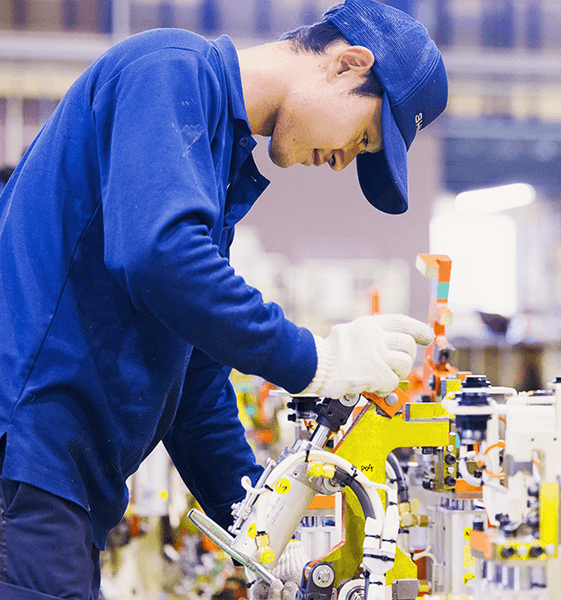

私たちは、高度な専門知識と技術を持つものづくりのプロフェッショナルで構成されています。

私たちはお客様のものづくりの夢の実現を最優先に考えております。社員一人一人が知識や技術を高め、お客様により良いものづくりのための設備を提供するために、全社一丸となって取り組んでいます。このようなプロフェッショナリズムが、各サービスの品質を高めています。

納入実績

長年にわたり、私たちは世界中のお客様に向けて、数多くのものづくりの自動化システムを提供し続け、生産性の向上をお手伝いしてきました。

その広がりは国内外にますます拡大しています。

多くの納入実績がイノベーションの波を起こし、新しい価値を創造し続けます。

COMPANY

OUR TEAM

最高品質のサービスは、人間力とチームワークあってこそ。当社では自社開発や国際的な営業活動など多彩な経験とビジネススキルを身に着けることも可能です。多様なプロジェクトと高度な技術環境で、プロのエンジニアとして成長できる職場です。